Engineering

Carnival Sound System Design

Project Overview

As part of a Master's thesis at the Harvard Graduate School of Design, a friend asked me to design a portable, DIY-style sound system evocative of those used in Caribbean carnival celebrations. My friend's thesis explored the construction of temporary community spaces, such as the ones created annually for carnival. The sound system was intended to reflect these spaces' grassroots spirit: high-impact bass, communal energy, and bold visual presence, and meet the technical requirements.

Design Requirements

The system needed to:

-

Function as a full-range sound system suitable for carnival-style street parties.

-

Deliver maximum bass and volume without distortion or damage to the system.

-

Cover the full audio frequency band.

-

Use the speaker drivers already owned by my friend.

-

It will be constructed from plywood using a CNC router.

-

Be transportable in a hand cart.

-

Be compatible with DJ equipment via RCA inputs.

-

Be powered by an affordable consumer amplifier.

-

Visually reflect the culture of Caribbean sound systems—a mix of 1960s cabinet design and DIY aesthetics.

-

Meet the standards and design rigor expected of a Harvard Graduate School of Design thesis project.

In the context of Caribbean carnival sound systems, these builds are as much about cultural identity and competition as they are about acoustics. Their distinct, bass-forward signature and visuals are meant to draw crowds and make a statement.

Component and System Design

Speaker Modeling in WinISD

Using WinISD, I modeled several enclosure configurations to evaluate SPL, low-end extension, and construction complexity. All designs prioritized ease of fabrication while maintaining performance. I tested configurations using both FTX1225 and Morel MW 1058 drivers.

Enclosure Variants:

-

FTX1225 (Vented, Single Driver)

-

Volume: 4774.2 in³

-

Tuning Frequency: 47.44 Hz

-

-3dB Point: 46 Hz

-

-

FTX1225 (Sealed)

-

Volume: 1728 in³

-

-3dB Point: 90 Hz (poor bass response)

-

-

Dual FTX1225 (Ported)

-

Volume: 11,000 in³

-

Port: 5.51" x 5.51", 1.24" length

-

-3dB Point: 43 Hz

-

-

Morel MW 1058 (Vented, Single Port)

-

Volume: 5000 in³

-

Port: 2.5" diameter, 5.45" length

-

-3dB Point: 23 Hz

-

-

Morel MW 1058 (Dual-Port Bandpass)

-

6th-order bandpass with front and rear chambers

-

-3dB Point: 26 Hz, but poor response linearity above roll-off

-

Added unnecessary complexity with no substantial acoustic gain

-

I kept port lengths short in all designs to reduce build complexity and tuning risk.

I checked each variation to make sure the simulated max cone excursion did not exceed the limit of the drivers, based on the parameters.

To stay within budget, I selected a 6000W consumer amplifier that supports six stereo zones, 8-ohm speaker loads, and RCA inputs for DJ connectivity. The amplifier’s limitations required both speaker drivers to receive the same signal, as passive crossovers were not feasible for this setup.

Final Design and Trade-offs

The selected design balanced SPL output, low-end performance, and ease of assembly:

-

One port per cabinet: Using one driver per cabinet gave my friend the option of choosing how he wanted to layout a three-box cabinet.

-

Vented enclosures: Provided greater low-frequency efficiency over sealed designs without added complexity.

-

DIY aesthetics: I preserved the visual language of traditional carnival systems, emphasizing bold, functional form by allowing my friend to build simple boxes to house the speakers. He could add aesthetic components to the design without impacting the performance in any major way.

I provided my friend with:

-

Detailed cabinet and porting dimensions

-

Guidance on where to place the vent and construction guidelines

-

General sound system guidance, such as

-

Adding banana jack connectors

-

Using speaker wire to ensure the system is safe

-

Reflection

This project was more than a technical build—it was a cultural artifact designed to perform and resonate within a specific social context. Working within material, budgetary, and aesthetic constraints pushed me to balance sound engineering with architectural expression. I was able to focus on providing flexible design recommendations that gave my friend confidence that he was going to build a great sound system.

Completed Speaker

Speaker Provided for Project

Render of Sound System Based on My Calculations Recommendations

The Port Hole was Incorporated into the Design Above the Driver

The Speaker Cabinets needed to be made out of Plywood andcut using a CNC Router

The Ventilator Project

Status: FDA authorized under EUA (See Section "Authorized Ventilators")

Goal: The Ventilator Project was founded to provide a solution for the increasingly critical ventilator shortage around the world for the COVID-19 crisis. It had to provide 24-hour support, be easily manufacturable with off-the-shelf parts, and cost only a fraction of existing ventilators.

At the start of the pandemic, I received a call from a volunteer from the project who knew I was an electrical engineer based in Boston, asking if I would join the project. When I joined the team, I was the sole electrical engineer. From that moment on, I join the team rapidly prototyping a ventilator. The goal was to design a low-cost ventilator that could be made from off-the-shelf parts that could be found around the world.

After speaking to front-line COVID-19 doctors and nurses, I created design requirements and designed the block diagram of the system to show the firmware and mechanical teams my plan and get their feedback. After that, I divided the next steps into the following tasks:

-Sensor selection and sourcing

-A wide selection of sensors was initially needed, O2, CO2, pressures, temperature, and humidity

-The design was simplified to a just pressures sensor

-All sensors would communicate over I2C and use 5V to simplify the power system

-Power system

-A power system had to work around the world and be able to work with unreliable power sources

-Safety system

-The system had to meet FDA's class 3 requirements for medical devices

-Battery Backup

-Per the FDA regulations the system has to operate uninterrupted if power fails for 2 hours

-To keep cost low and parts easy to find, I selected an off the shelf computer back battery.

-Hardware Alarm

-If critical components of the system failed, such as the power supply, an alarm would have to be triggered

As the team lead, I managements a remote team of remote engineers as well as interviewing and managing an on-site team later on.

In Winter 2021, the prototype ventilator was featured at Cooper Hewitt: Smithsonian Design Museum in New York City, as part of their exhibit "DESIGN AND HEALING: CREATIVE RESPONSES TO EPIDEMICS".

No Silence

Status: Beta

Goal: To cut out the quiet sections of an audio recording of a meeting or a lecture. Removing these sections would reduce listening time.

The idea of this project came from the inefficiencies of live spoken recordings. So much of listening time is wasted on unnecessary sections. Could an automated process remove the unwanted sections?

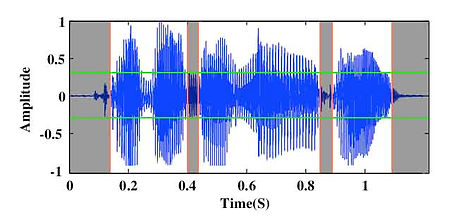

My first step in solving this problem was looking at a .WAV file of a recording and assigning variables. On the right, I have lines representing Threshold (Green) and PreWait and PostWait (Red). With these points established, I can remove the sections in grey.

Requires Matlab 2017a or newer